Vickers hardness testing principle

Description

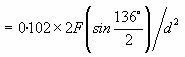

The Vickers hardness test uses a square-based pyramid diamond indenter with an angle of 136° between the opposite faces at the vertex, which is pressed into the surface of the test piece using a prescribed force, F. The time for the initial application of the force is 2 s to 8 s, and the test force is maintained for 10 s to 15 s. After the force has been removed, the diagonal lengths of the indentation are measured and the arithmetic mean, d, is calculated. The Vickers hardness number, HV, is given by:

HV = Constant × Test force / Surface area of indentation

Standard Vickers Scales

|

Micro-hardness |

Test force |

Low-force |

Test force |

Macro-hardness |

Test force |

|

HV 0.01 |

0.09807 |

HV 0.2 |

1.961 |

HV 5 |

49.03 |

|

HV 0.015 |

0.1471 |

HV 0.3 |

2.942 |

HV 10 |

98.07 |

|

HV 0.02 |

0.1961 |

HV 0.5 |

4.903 |

HV 20 |

196.1 |

|

HV 0.025 |

0.2452 |

HV 1 |

9.807 |

HV 30 |

294.2 |

|

HV 0.05 |

0.4903 |

HV 2 |

19.61 |

HV 50 |

490.3 |

|

HV 0.1 |

0.9807 |

HV 3 |

29.42 |

HV 100 |

980.7 |

Standards

|

BS EN ISO 6507-1:2018 (BS 427:Part 1:1961) |

Metallic materials. Vickers hardness test. Test method |

|

ASTM E92-17 |

Standard Test Method for Vickers Hardness of Metallic Materials |